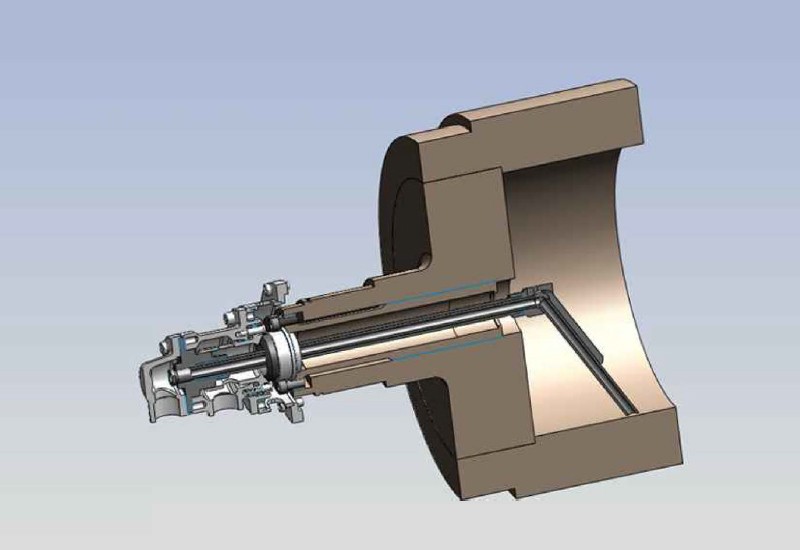

Froond rotating joint and stationary syphon

The Froond Joint is a unique system with high performances in the removal of the condensates while enabling extremely reduced maintenance. The Froond joint is adaptable to any corrugator cylinders, so as to ensure a simpler spare parts handling. Thanks to the flanged coupling of the Aerothermic Fomat joint, that guarantees a perfect alignement and position to the cylinder, a fixed suction system can be obtained with a minimal distance to the bottom (only few millimeters).