Integrex series

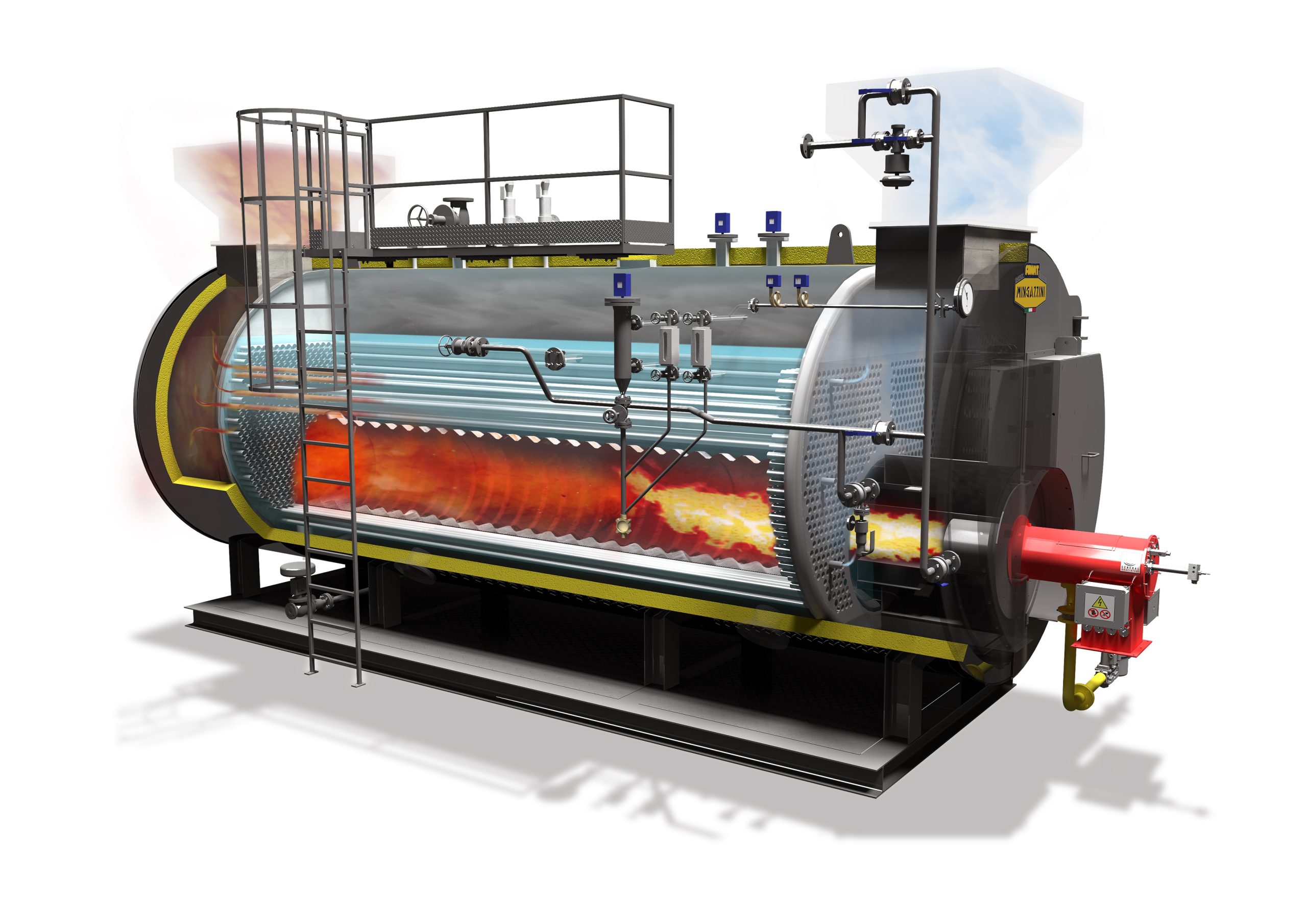

After many recovery boilers installed, Aerothermic Fomat realized that the high amount of steam produced by these boilers made the traditional boiler installed in the mill a low-performing product, obviously due to the lower demand for steam. To solve this problem and further reducing consumption, Aerothermic Fomat has developed the exclusive Integrex series, in collaboration with an established brand in boiler manufacturing. This series combines in one unit the recovery boiler and the burner, thus ensuring a further reduction in consumption.

The burner works only if necessary and does not remain in standby to be able to function as steam is needed or, in case of lack of recovery steam, can generate the steam needed by the machine. Unlike our competitors who use an after-burner, the system has the highest yields and the fumes are then exploited in our recovery unit. In case of new installations, the advantages also include lower power consumption, lower installation costs and reduced space.