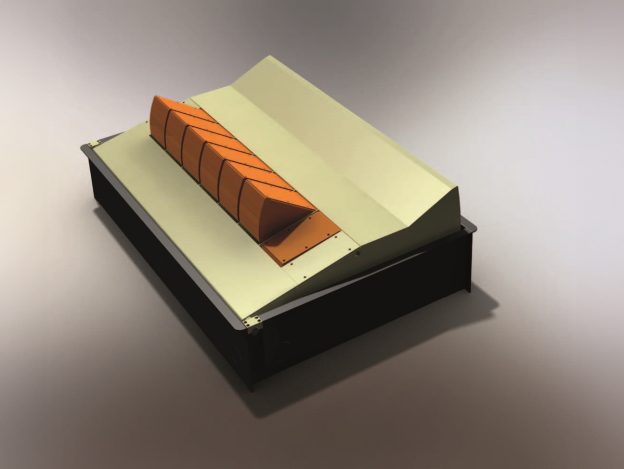

ST3000-N Stopper

The ST3000-N Stopper is designed to allow the stoppage of incoming rolls from the cradle of the rewinder and transfer them to the wrapping machine or other. The stopper consists of a metal framework installed flush with the floor, containing N liftable sectors. These sectors, each actuated by a pneumatic cylinder, are raised before the unloading operation to create a barrier, and halt the roll at the desired point. Both the framework and individual sectors are equipped with sensors to detect their high/low positions.

The stopper’s movements are interlocked with the winder controls: unloading the winder is only possible when the framework is lowered and the sectors are raised. The ST-N cannot ensure the automatic transfer of rolls narrower than 300 mm. For this reason, a special function has been integrated into the control panel to allow bypassing automatic unloading from the ST-N and enabling manual pushing of rolls less than 300 mm (single or grouped) by an operator.